Tracking Systems improve the economics of certain solar

projects

By Anthony Chico Pio Rebelo

chico.rebelo@sgurrenergy.com

Download as PDF

EXECUTIVE SUMMARY

Developers face a number of challenges when creating proposals for solar projects and

with the recent cancellation of power purchase agreements (PPAs) awarded to

recognised developers, none of these challenges is more relevant in today’s market

than the availability and acquisition of land. This consequently leads to the

question of whether to employ a fixed-tilt (FT) system or a horizontal single axis

tracker (HSAT) system to achieve desired energy targets.

SgurrEnergy India (SEI) recently addressed this question by performing an analysis

comparing the popular FT system to the HSAT system often used in the U.S.

INTRODUCTION

Solar photovoltaic (PV) modules are secured on mounting structures that provide structural

support and keep them oriented in a direction that allows them to receive maximum sunlight.

The tilt angle is optimized for site conditions of the given location. In India, most of

these systems are fixed tilt (FT) systems that do not move. However, PV panels can be

mounted on tracker systems that move throughout the day to keep the PV panels oriented

toward the sun and at the optimal angle for productivity. There is no other single

balance-of-system (BOS) component that can increase a PV system’s performance like a

tracker. Tracking systems can increase generated output by 10% to 25% compared to FT

mounting structures, but they can come with drawbacks in the form of site preparation costs

and moving parts that can require specialized maintenance.

Within the tracker systems group, there are two main subcategories; single-axis trackers that

turn on one axis and dual-axis tracking systems that turn on two axes. Single-axis trackers

are further subdivided into vertical single axis trackers, tilted single axis trackers, and

horizontal single axis trackers (HSAT). The following analysis performed by SEI focuses on

comparing HSAT systems to FT systems.

COMPARING THE TWO SYSTEMS

The SEI analysis compares the price, components, and performance of a 1.9MW FT system to a

1.2MW HSAT system. Simulations of both systems were set up using identical conditions on a

five-acre sample area in the high resource region of Bhadla in Rajasthan, India. SEI used

the photovoltaic simulation software PVsyst to optimize the layout and operational

parameters for each mounting system and simulated results were gathered for a one-year

period.

The question of which system would be most economical yielded mixed results for the sample

area. Although the FT system would generate approximately 34% more energy (P50 generation)

than the HSAT system and deliver a superior ground coverage ratio (GCR), the higher capacity

means that the FT system needs twice the number of inverters, which raises the installation

price by INR 10 million. This suggests that the HSAT system could be the more affordable

option, but the analysis did not consider the land specifications needed for an HSAT system

to function at its best and, by extension, the potential site preparation costs.

The SEI analysis compared FT and HSAT systems by looking at the following key factors

affecting solar project pricing and generation outcomes under identical conditions. These

are:

- Energy yield

- Ground coverage ratio (GCR)

- Inverter loading

- Quantum of module

- Balance of system (BOS) cost

The plant layout was configured to account for the influence of land boundaries and general

topographic conditions on system configurations. In certain cases, land conditions can have

a significant impact on mounting system installation costs. For instance, since HSAT system

function best on a land gradient of 3° or less, costly land levelling procedures could be

required before installation at certain sites.

Simulation results were recorded and the key factors of the two systems were compared.

Current market tariffs and rates were then applied to the simulated results.

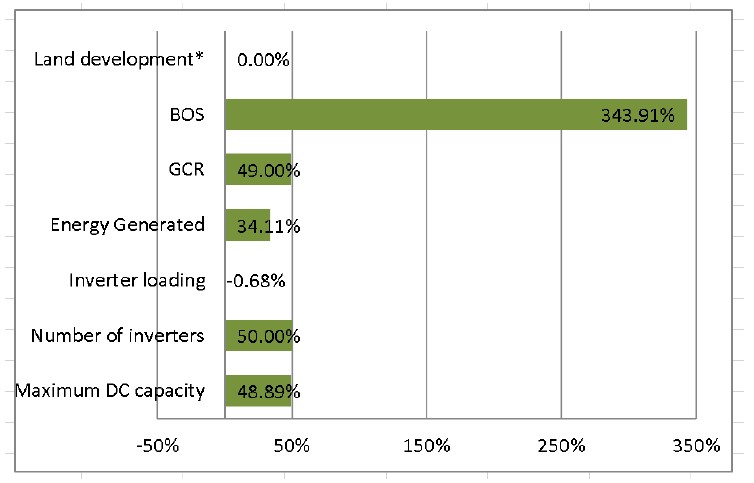

In Error! Reference source not found. below, the main parameters of an FT system were

compared with those of an HSAT system and presented as a percentage increase or decrease.

Similarly, the financials were computed using current unit prices and tariffs.

It must be stated that this is a high-level analysis that only considers basic assumptions.

Unit prices and tariffs are vary widely based on product suppliers, installation regions,

and local government policies.

| Parameters |

Fixed Tilt System |

HSAT Comparison Expenditure/revenue variation (INR)1 |

| Maximum DC capacity (number of modules) |

48.89% |

-188,16,000 |

| Number of inverters |

50.00% |

-10,00,000 |

| Inverter loading |

-0.68% |

- |

| Energy Generated |

34.11% |

5,88,75,126 |

| Ground coverage ratio (GCR) |

49.00 |

-2 |

| Balance of System Cost (BOS) |

343.91% |

-4,03,86,386 |

| Land development |

- |

- |

Table-1: Comparison of the initial development costs of a fixed tilt (FT) system versus a

horizontal single axis tracking system (HSAT) system

| Parameters |

HSAT |

FT |

| Energy generated (kWh) |

2,500,695 |

3,353,643 |

| Lifetime energy generation3 (kWh) |

57,537,205 |

77,162,247 |

| Ground coverage ratio (GCR) |

38.3% |

57.1% |

| DC capacity (kWp) |

1,280 |

1,907 |

| Number of module |

4,000 |

5,960 |

| AC capacity (kW) |

1,000 |

1,500 |

| BOS (INR) |

11,743,158 |

52,129,544 |

1. Negative values indicate a higher expenditure for FT systems.

2. Land prices fluctuate by state, utilization, social significance and topographic

conditions.

Figure 1: FT cost relative to HSAT

DECIPHERING THE DATA

SEI’s analysis of the simulation information allowed the following deductions to be drawn:

- A FT system offers multiple module racking possibilities, with the possibility of

achieving a higher DC power density in each area. Mounting options, such as tilt, are a

function of the location of the project. In the simulation exercise, the FT system

accommodated an array capacity that was approximately double that of the HSAT system on

the considered land parcel. This extra FT installation capacity was made possible by an

additional investment of close to INR 19 million, assuming a unit price of INR 30/Wp.

- Inverter loading is designed to handle the associated peak direct voltage (DC) capacity

of a system. Since the FT system can accommodate almost double the array capacity of the

HSAT system, it follows that the alternating current (AC) system would double too,

meaning that twice the number of inverters will be needed for an FT system.

Using the

current inverter rate of INR 2/W, the additional AC capacity required translates

into an

additional expenditure of INR 10 million for the FT system.

- Ground coverage ratio (GCR) is defined as the ratio of the PV module area to the land

area utilized. This ratio is ideally kept as high as possible. Tracking systems like the

HSAT tend to use more land because units must be spaced out further apart to keep them

from shading one another as they track the sun, which increases land use and the

associated land costs for the developer. Tracker manufacturers recommend a maximum land

gradient of 3° for deployment of HSAT systems, which means these systems may require

additional land preparation costs for levelling, grading, and cutting. HSAT systems can

be difficult to install in the randomly shaped plots typical of PV plants. Due to the

tilt and the mounting arrangement chosen for the study, the FT system returned a

GCR

that was almost double that of an HSAT system.

- Although module prices still constitute a large chunk of total project cost, the drop

in module prices in recent years has made the balance of system (BOS) cost an

increasingly significant component of overall project cost. To quantify this expense,

SEI’s research considered the BOS costs of previously executed projects that were

developed by different developers at different locations. Since it was possible to

install a higherpeak capacity within the predefined land boundaries using FT

architecture, this translated into a higher BOS cost for the FT system. In fact, the

cost for the FT system was approximately 4.4 times higher than that of a comparable HSAT

system.

- Return on investment (ROI) is represented by the energy generated. This parameter

results from all project specifics ranging from the selection of the location, or solar

resource, to O&M strategies like module cleaning. In the analysis, wherever possible,

similar losses were considered so that performance could be evaluated on a level

platform. In real plant design parameters, the actual generation ratio may vary.

In the

analysis, the FT system generated approximately 34% more energy (P50 generation).

This

implies that the surplus generation of the FT system will be higher than that of the

HSAT system over a 25-year period. The study used an annual degradation

guaranteed by

most Tier-1 module manufacturers.

- Among other findings, it was discovered that the unit price of each system varies based

on the manufacturer. For example, systems developed in China or made locally in India

are less expensive than similar systems from European manufacturers. Another component

affecting installation economics is the wide variation in tariffs for different areas.

Though tight margins and higher land development costs for the HSAT system has made FT

systems more popular, the study results indicate that there are instances where the HSAT

system makes sense under current tariff structures.

Results showed that developing the 1.9MW FT system would be more expensive than developing

the 1.2MW HSAT system. However, the study did not consider land development costs or

the long-term O&M cost of trackers. Tracking systems tend to need maintenance

more often due to their moving parts and in places where labor costs are high and spare

parts are not readily available, this can meaningfully impact project economics. These

factors could swing the outcome in favour of a FT system under a different set of

conditions.

HSAT SYSTEM IS BEST UNDER CERTAIN CONDITIONS

The analysis found in favour of the HSAT system, but not without its caveats. Tracker

technology is relatively new and the long-term performance of these systems is still being

determined. Durability tests on HSAT components are addressing some of these concerns and

manufacturers are building up their service capabilities. However, until those capabilities

exist, the failure of a tracking system can cause longer than expected downtime due to

reasons such as the limited availability of spare parts. No such drawbacks exist for FT

systems under normal conditions. Module cleaning for HSAT systems could be simplified and

made faster by optimally tilting the modules, but robotic cleaning is not yet available.

CONCLUSION

The question of which type of mounting system is best for a project must be evaluated on a

case-by-case basis that takes various factors into account. What is most efficient and cost

effective for one project may not be the best choice for another. Independent power purchase

agreements (PPAs) would be wise to take these factors into consideration.

Solar PV plant with HSAT installation

Download as PDF