Solar PV Projects – The Case for Independent

Construction

Monitoring

By Dhiraj

Madje

dhiraj_madje@sgurrenergy.com

Download as PDF

EXECUTIVE SUMMARY

A solar PV project is divided into various essential aspects of infrastructure such as:

electrical engineering, civil engineering, module mounting structures, weather

monitoring

stations, and supervisory controls. In order for a solar power plant to achieve the

desired

generation values, it is vital that the design conceptualization translates into

implementation

on the ground. This means that every aspect of engineering and construction needs to be

properly

validated, documented, and easily accessible during the project cycle.

Th article provides a high-level overview on the importance of independent monitoring

during the

construction phases and its implementation techniques with the help of site quality

assurance

documentation. The presence of independent engineers during various project phases such

as

initiation, planning, and execution will help solar power plant developers and

engineering,

procurement, and construction (EPC) companies achieve acceptable solar power plant

quality

standards.

INTRODUCTION

Solar PV power plants are often considered to be simple construction projects, but the

reality is

that essential methodology and implementation techniques are often ignored because of delays

starting the project or the need to meet the commercial operational date (COD) deadline in

the

power purchase agreement (PPA).

Basic health, safety and environment (HSE) site quality documentation such as the field

quality

plan (FQP), installation checklist, pre-commissioning checklist, and testing checklist are

frequently treated as being unimportant. Even imperative guidelines that detail project

construction activities such as the method of statements (MOS) or technical work procedures

(TWP) are regularly ignored or neglected by the EPC. These plans and procedures can be

implemented and adhered to as a project progresses with the help of independent engineers.

NEED OF CONSTRUCTION MONITORING

These actual images from project sites illustrate low quality

civil engineering work that was executed in the absence of supervision or construction

monitors.

Figure (A)

Figure (B)

Lack of supervision and underutilization of implementation quality checklists has resulted in

structural post pile cap erosion after heavy rains in Figure (A). Improper grouting and

insufficient finish to the foundation bolts of the structural pole can be observed in Figure

(B).

Figure (C)

Figure (D)

Figure (C) shows deformed structural bracing members for the installation of module mounting

structures that is the result of implementation quality checklists not being used along with

no

independent oversight. Deformed bracing can be replaced, but in Figure (D) the support post

has

been installed at an incline, which will result in instability to modules. These low quality

mistakes are repairable, but at a high cost and the rework will consume precious time

towards

meeting project completion deadlines. Such issues have been observed to be accepted by

developers as defects. Quality lapses are commonly observed and noted in the electrical

infrastructure as well. Modules can be damaged or even broken beyond acceptable limits,

leading

to higher costs for project installations. Compromised quality can lower energy generation,

causing a project to fall short of the target output for which it was selected.

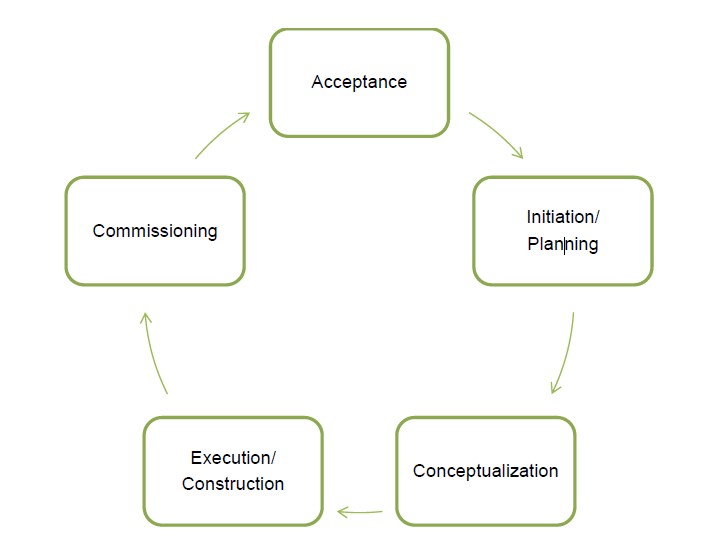

To mitigate the above concerns, solar PV project construction should typically progress

through

the following stages: planning, conceptualization, schematic design, construction design and

drawings, and most importantly construction administration to ensure that quality control

and

assurance is implemented throughout the project lifecycle illustrated in Figure (E).

Figure (E): Project Life Cycle

Appointing a designated team of engineers for construction monitoring during the project

phases

to confirm the implementation of quality control and assurance systems would achieve

acceptable

quality plant standards at delivery. These engineers would principally help contractors

follow

consultant, developer, and manufacturer recommendations during installation, testing, and

commissioning for all the project components. They would compile records of all the

installation

and testing results in the form of checklists, which will in turn make the project

documentation

stronger and more useful for future O&M.

Construction monitoring of solar PV plants needs to be performed in the interest of quality

control and to resolve issues that arise due to non-conformance to standard industry

practices.

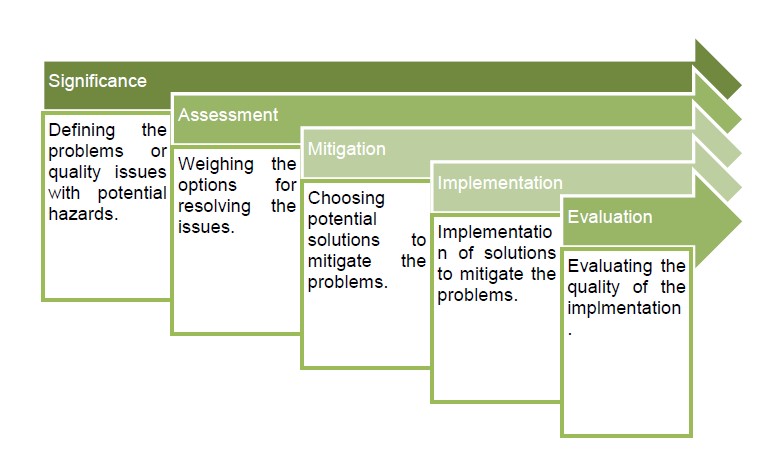

In this model, every task is completed in a sequential manner and the steps include

resolving

common problem or lapses as shown in Figure (F).

Figure (F): Quality Control Steps

CONCLUSION

Project construction monitoring teams would apply their knowledge, skills, tools, and

techniques

to project activities to assure they meet established project safety and quality

requirements.

They would also be proficient at helping EPCs in implementation aspects such as following

quality plans, utilizing check lists, completing compliance reports, resource management,

etc.

It is essential for the solar industry in India to appoint construction monitoring teams so

that

a standard level of project construction can be achieved and maintained.

Download as PDF