Floating solar system: A case for String inverters

Anthony Chico Pio Rebelo

chico.rebelo@sgurrenergy.com

Dhiraj Madje

Dhiraj.madje@sgurrenergy.com

Download as PDF

EXECUTIVE SUMMARY

Utility scale Solar PV projects is gaining global acceptance and its growth attaining

an almost exponential trend, new challenges are emerging in the ever competitive

landscape. Floating solar, also known as floatovoltaics is one of the emerging

avenues for deployment of PV systems. This technical article addresses the advantages and

the essential challenges associated with implementing such systems, along with

solutions adopted by developers.

INTRODUCTION

The global floating solar PV installation by the end of 2018 is expected to touch 1.1GW,

with China accounting for most of the capacity and the largest plant of 40MW.Research

firm IHS Markit has listed floating solar PV as one of the global solar market trends to

make a significant impact, where it is predicted that the industry will move from a

niche application to a steady market uptake. Acquiring land suitable for implementation

of ground mounted projects at affordable price is getting challenging with the price of

solar expected to follow a downward trajectory. This may be further compounded with

countries enforcing environmental regulations. Floating PV systems may be considered as

a reasonable solution in such situations. As the PV sector gets competitive and more

players enter the market, this will lead to increased innovation in products, designs

and market trends.

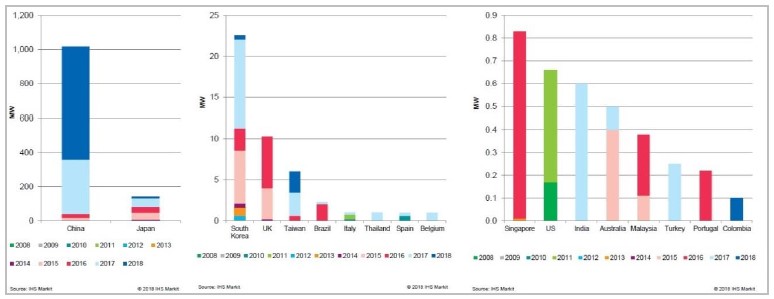

From the first floating plant built in California (400kWp) for a winery in the year 2007,

the technology has gained an acceptance in Japan in its early days of deployment. This

can be attributed to the dearth of suitable land for deployment and generous feed in

tariffs. As of 2018, China leads the rest in the implementation of floatovoltaics, with

most installations achieving commissioning in 2017 and 2018. Global floatovoltaics

installation of projects over 100kW is presented in Figure 1. The data indicates China

accounts for over 85% of total installation.

Figure 1: Global floatovoltaics installation

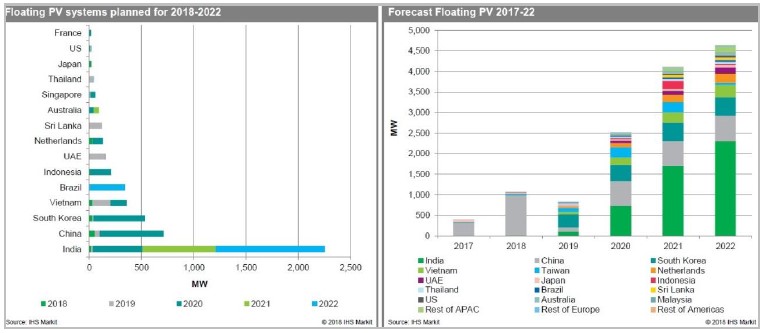

Development in Indian started with the commissioning of a 500kW project in 2017. This was

followed-up by a 2MW project located on the Mudasarlova reservoir in 2018. Development

is expected to ramp-up with SECI having previously proposed 10MW of deployment. An RfS

floated in September 2018 also aims to construct 150MW of solar PV capacity on the

Rihand Dam in UP, India. HIS Markit estimates a considerable capacity addition in India

from 2020 to 2022 and the growth is expected to drive up global installation capacity

during the period as suggested in Figure 2.

Figure 2: Projected global deployment of floatovoltaics

BENEFITS OF FLOATOVOLTAICS

Floatovoltaics can be implemented on inland water bodies such as lakes and ponds or even

offshore. The latter involves additional engineering challenges such as tidal effect,

waves, saline environment etc. and is still in the development phase.

Floating solar offer a range of advantages such as:

- Reduced evaporation from reservoirs.

- More efficient system due to lower thermal losses resulting from cooling from

water.

- No cost associated with procuring land.

- Lower algae growth.

- High energy gain due to spectral response for select PV technologies.

Conventional Ground mounted metal Module Mounting Structures accounts for approximately 6

- 7% of the project cost. This is dependent on the region and structure design. The cost

of metal is steadily increasing, thereby resulting in an even greater contribution to

CAPEX. These structures need civil works to varying degrees which adds to the cost of

land preparation. All of this hardly applies to floatovoltaics.

Installation of the main array of the floatovoltaic system is generally simplified due to

foundation work not being required. Systems are installed on the banks of a reservoir,

usually by linking multiple floating units and pulled out onto the reservoir once

linked. As units are modular, this stage of installation can proceed quickly. However,

structures must be able to withstand variation in water levels and strong winds.

Floating plants are comparatively less affected by soiling; for plants that do, logistics

of sourcing water is eliminated as it is readily available at site. It is important to

access the quality of water prior to its utilization for cleaning. Aeration units

powered by the floatovoltaics can be installed for oxygenation of reservoirs to improve

water quality. Restricting sunlight from reaching the water surface, floatovoltaic

plants also prevent the growth of algae, which in turn improves the dissolved oxygen and

promotes growth aquatic life.

Thermal effects on the modules account for most losses from PV systems. This can be as

high as 12% in tropical climates such as the Indian subcontinent. High thermal capacity

of water which acts as a heat sink providing floating plants a way to naturally cool

modules, thereby yielding a higher generation and system performance. The presence of

floatovoltaics also reduces water loss due to evaporation. The quantum of losses are

region specific, this can be particularly aggressive in tropical climates.

IMPLEMENTATION CHALLENGES

Besides its advantages, floatovoltaics comes with its set of challenges too but

developers have worked around some of these to design more efficient systems. One such

development is the use of string inverters in floatovoltaics.

Current floating solar projects utilizing central inverters are primarily designed for

ground mounting application and not ideal for floating PV application. Their low ingress

protection (IP) is one such example. Inverters may be propped on reservoir surfaces or

located on the reservoir bank. PV plants with floating inverters are exposed to a

harsher environment and may require more frequent O&M. Accessing and performing the

required service on the affected floating inverters can prove cumbersome. High humidity

is also responsible for PID effect.

As central inverters are connected to a larger array of modules covering a greater area,

the voltage drop is higher and consequently so is the power loss. Connecting a larger

array requires cables of varying lengths which cause string mismatch. This is harder to

mitigate as central inverters are often equipped with only 1 MPPT. String inverters are

connected to smaller array that keeps the mismatch due to string length variation to a

minimum. Often equipped as multi MPPT units, string inverters aid in further reducing

mismatch resulting in higher system efficiency and energy generation.

Design requirement for central inverter floaters are more challenging when compared to

floaters for PV modules. In case of a string inverter, these can be mounted on floaters

for modules and eliminate the need for separate floatation units.

The demands of bigger inverter floaters design is only exceeded by the floater designs

for the transformers which is even greater. In addition, to prevent oil leakages, these

transformers are almost always dry type, thereby increasing project costs. The need for

dry type transformers is also eliminated where in Oil type transformers may be installed

along the banks of the reservoir. The need for combiner boxes (with higher IP

requirements) would also be redundant.

Floating platforms for central inverters, string inverters and transformers

Implementing a 1,500V system architecture increasing system risk and a higher emphasis on

safety is required. This results in higher requirements for system safety due to high

probability of PID, DC arcing risk, residual leakage current etc. and due to high

humidity these effects gets intensified. Overall AC cable length in string inverters is

greater than the DC cable length. This implies a higher probability of safely quenching

AC arc due to higher number of zero crossings. Some central inverters are not equipped

with RCD’s which may result in HSE issues.

Insulation impedance depends on environmental conditions such as humidity and is lowered

considerably in the case of floating plants. A generic disadvantage of central inverters

is their low Insulation impedance when compared to string inverters. Huawei claims their

50kW inverter has a typical impedance of about 410kohms. This is considerable lower for

central inverters, typical 33.3kohms for a 1MW inverter. If the insulation resistance of

the inverter does not comply with IEC 62109 requirements for non-isolated systems, the

system is required to indicate faults (alarms) and disconnect from the mains (inverter

shutdown). This may result higher downtime and revenue loss in plants using central

inverters.

RS485 communication is the standard and in most cases the only mode of communication

provided to central inverters. This system is particularly susceptible to the

environment and prone to failures. Deployment in wet environments can result in their

damage and placing them alongside power cables makes them prone to interference. In the

event of a failure, fault detection and rectification is a laborious task. All of these

shortcomings may lead to particularly high O&M costs. Modern string inverters have a

plethora of communication options. These may include USB, Bluetooth and PLCC

communication options in addition to RS485.

An example of a string inverter with features to counter challenges posed by

floatovoltaic application is Huawei’s SUN2000 series. Some of the features packaged into

the inverter that lends itself particularly useful to floatovoltaic application are:

- Up to 6 MPPT’s

- IP65 protection

- Type II surge protection

- PLC support

- Residual current monitoring unit

- Fuse free design

- Anti-PID technology

To observe the floatovoltaic installation deployment of a SUN2000 series, SgurrEnergy

India (SEI) visited the 20MW Zhejiang Jiande Floating PV Solar Project in Zhejiang

province of China. The project was commissioned in June 2017 and is owned by Powerchina

Huadong Engineering Company Limited (HDEC). Covering a reservoir area of 66acres, the

project is implemented with dual glass modules and 373 Huawei SUN2000-50KTL string

inverters. Site photographs are presented in Figure 4.

Figure 4: Zhejiang Jiande Floating PV plant utilises SUN2000-50KTL inverters

The array structures were assembled on land and later drawn out to the reservoir where

concrete anchors are used to stabilize the structures. Data provided by Huawei on the

performance of the Project over a 10 month period indicates high plant PR; Table 1.

Table 1: 20MW Zhejiang Jiande Floating PV Solar Project performance

| Month |

Total insolation (kWh/m2) |

Energy injected to grid (kWh) |

PR (%) |

| July 2017 |

- |

23,55,939.62 |

89.00 |

| August 2017 |

000.676 |

25,55,102.55 |

89.00 |

| September 2017 |

131.094 |

20,17,750.00 |

76.16 |

| October 2017 |

119.859 |

19,05,750.00 |

77.88 |

| November 2017 |

088.757 |

14,50,750.00 |

79.02 |

| December 2017 |

095.284 |

15,19,000.00 |

77.78 |

| January 2018 |

071.159 |

11,81,250.00 |

79.74 |

| February 2018 |

093.921 |

15,71,500.00 |

79.68 |

| March 2018 |

127.673 |

21,22,750.00 |

79.53 |

| April 2018 |

142.472 |

23,50,250.00 |

79.48 |

The data hints at some discrepancies in the recordings such as insignificant irradiance in

August 2017 and low inverter efficiency particularly in November 2017.

CONCLUSION

The last few years has seen floatovoltaics emerge from a niche market to mainstream adoption

for capacity addition. Increasing environmental clearances and high land prices is aiding in

adoption of floating plants where no such requirements currently exist. Of the current

global capacity, Japan leads the way in terms of installed capacity primarily due to land

availability and federal policies.

Floatovoltaics offers a variety of advantages such as non-reliance on metal structures and

its increasing cost, lower thermal losses from modules due to natural cooling, ease of

installation, reduced soiling, better reservoir health, stemming evaporation that is

particularly high in tropical regions. The overall gain is region dependent and aligns well

with deployment in warmer locations.

As with any emerging technology, there are hurdles to overcome in achieve mainstream

acceptance. The selection of system architecture such as choosing between central or string

inverters, 1,000V or 1,500V system also dictates the challenges posed in implementation of

projects. For floatovoltaics these challenges include; requirement of equipment with higher

IP rating, stronger PID effect, string mismatch, use of dry transformers, communication

practices, insulation impedance and O&M challenges in some instances.

Products available in the industry which are suited for implementation in floating plants

include the SUN2000 inverter series by Huawei. This inverter has up to six MPPT’s, IP65

rating, fuse free design, PLC support etc. Some of the advantages offered are:

- Less frequent and lower O&M cost

- Avoiding use of components with high IP rating; such as combiner boxes, cabinets etc.,

and thereby reducing cos t.

- Lower mismatch losses, higher system and greater generation due to less variation in

cable lengths and 6 MPPT’s in the 95KTL (4 MPPT’s in the 50KTL).

- Avoiding the need for large and expensive floaters for inverters and transformers.

- Lower HSE risk when implementing 1,500V system as compared to a central inverter based

1,500V system due to lower arcing probability.

- High insulation impedance and compliance to IEC 62109 as compared to central inverters.

This may result in tripping of central inverters, higher downtime and revenue loss.

- Lower PID due to anti-PID technology.

- Multiple communication modes such as RS485, PLCC, USB and Bluetooth when compared to

central inverters.

Download as PDF