Bifacial PV module technology has seen a steep increase in interest from the industry on

the back of similar success of PERC technology enabled PV modules. The technology

however has been around for some time, with commercial production in place for over a

decade. So how are the conditions different now from a few years ago? What is driving

this widespread adoption of bifacial PV modules in the present time?

Several factors have made adoption of bifacial modules conducive from a technical and

commercial standpoint. The technical and commercial success of PERC models, the drop in

module prices, higher efficiency, decrease in the BOS cost such as trackers, etc. have

made adoption of the technology lucrative. An added benefit is the work put in by the

federal and private participants such as NREL, PVsyst and other component manufacturers

to improve the accurately of computed system yield, module durability and optimum

performance in general.

Peak yield from a bifacial system requires the optimization of several factors and to

varying degree of influence. These include albedo, ground coverage ratio (GCR),

elevation etc. The industry has also realized that coupling bifacial modules with

trackers returns a higher generation than bifacial modules on a fixed tilt system,

thereby lowering the Levelized Cost of Energy (LCOE) and improving the project Internal

Rate of Return (IRR). Some estimates claim bifacial gain as high a 30% with the right

conditions. As the technology matures and prediction techniques improve, more accurate

estimates of the gain offered by bifacial modules will be possible.

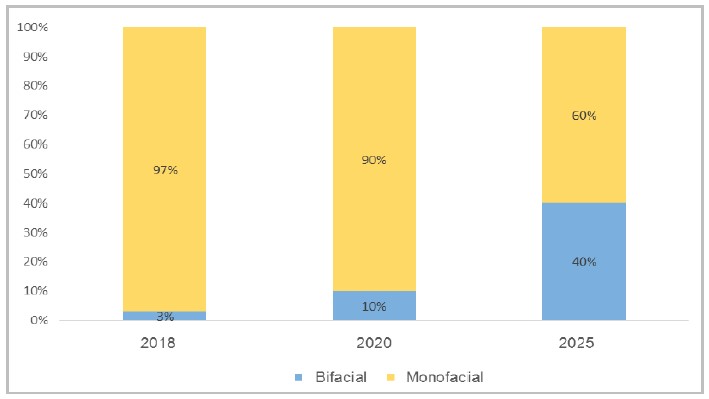

A Bloomberg report for H1 2018 puts the market share of bifacial modules at 3%, which is

expected to grow to 40% by 2025 as shown in Figure 2

Figure 2: Bifacial module market share

With module prices continually falling, bifacial PV modules are expected to replace

monofacial modules, the current workhorse of the industry.

The paper starts with the basics of bifacial modules and covers the factors that need to

be addressed if such a system has to be optimized, as a one size fits all approach is

not possible.

WHAT ARE BIFACIAL PV MODULES?

As the name suggests, bifacial PV modules can generate energy from the front and rear

side of a PV module. Unlike mono-facial modules, the rear side of bifacial modules is

lined with cells to capture reflected and diffused irradiation. A comparison of the two

is shown in Figure 3. The nameplate power of the rear side of the modules is however

less than the front side. Bifaciality factor quantifies the STC-rated power of a

bifacial module’s rear side in relation to the front-side power. These ratios range

between 55% and 95%.

-and-monofacial-PV-modules-(right).jpg)

Figure 3: Bifacial PV modules (left) and monofacial PV modules

(right)2

Bifacial technology is essentially a derivative of Passivate Emitter and Rear Cell (PERC)

technology, as the name suggests, both having a rear passivation layer that improves the

ability to trap light. The difference being replacing the fully metalized rear electrode

(aluminium layer) in PERC with selective metallized contacts that allow light to pass as

shown in Figure 4.

-and-bifacial-cell-(right).jpg)

Figure 4: PERC cell (left) and bifacial cell (right)3

HOW BIFACIAL MODULES ARE DESIGNED

To boost energy generated from the module, every part of the module is designed to

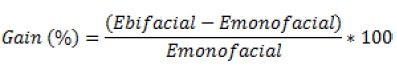

maximize light absorption and consequently higher energy gain. The Gain of a bifacial

unit is defined as;

Several factors influence the overall gain. These include:

- Cell technology

- Module design

- Installation choice

- Ground conditions

- Surface reflectivity

Choice of cell technology relates to selection of n/p-type and mono/poly PERC.

Installation choices relates to fixed/tracking system, tilt, pitch etc. Ground

conditions relate to irradiance, latitude, longitude etc. Surface reflectivity is known

as albedo. While module design is discussed in this section, installation choices and

surface reflectivity will be debated in the following section.

Area between the cells is designed to either allow passage of light to the rear side or a

layer called ceramic glass which is essentially a reflective layer is added under the

cell layer as shown in Figure 5. Manufacturers claim using ceramic glass increases the

nameplate rating by 5W.

-and-ceramic-glass-(right).jpg)

Figure 5: Fully transparent rear glass (left) and ceramic glass

(right)4

To achieve light transmission, early variants of bifacial modules that appeared in the

market were frameless and dual glass. Manufacturers claimed these designs afforded the

module low moisture transmission rates and made the module less susceptible to PID among

other benefits. Currently available bifacial modules are available as dual glass or with

clear backsheet. In sandy environments, double glass models provide an additional

barrier. Using transparent backsheet is beneficial when lightweight models are required.

However, transparent backsheets are challenged by UV radiation and hence testing to

ascertain their weakness is crucial.

According to DuPont, testing polymer-based backsheets with controlled humidity is the

prime test in combination with thermal cycle for determining embrittlement effects.

The choice of using framed or frameless models depends on the application. For tracking

and floating solar plants, framed models are better suited for their higher stability

and resistance against mechanical stress. Due to the nature of the design requirement,

rear-side busbars is necessary and cell stringing mirrors that of the front side.

Frameless modules are also less prone to PID.

A key requirement for optimal performance of bifacial modules is to minimize shading on

the rear side. Junction boxes are hence become smaller and in some cases separated into

multiple units placed along the panel’s edge. All of this results in better thermal

management and hence bifacial modules usually have a better temperature coefficient than

conventional monofacial modules.

The robustness of bifacial module design in general is reflected by the lower annual

degradation rate. The current industry average is 0.5%/year.

PLANT DESIGN AND FACTORS TO BE CONSIDERED

Energy generation and Performance Ratio (PR) depend on several factors. While the choice

of cell technology and PV module design form the foundation for an optimum system, plant

layout and associated ground conditions can facilitate or hinder these objectives.

To optimally operate a bifacial PV plant it is essential to ensure adequate reflected

light is incident on the rear side of the module. This is essentially dictated by the

albedo, which is defined as the fraction of solar radiation reflected from Earth into

space.

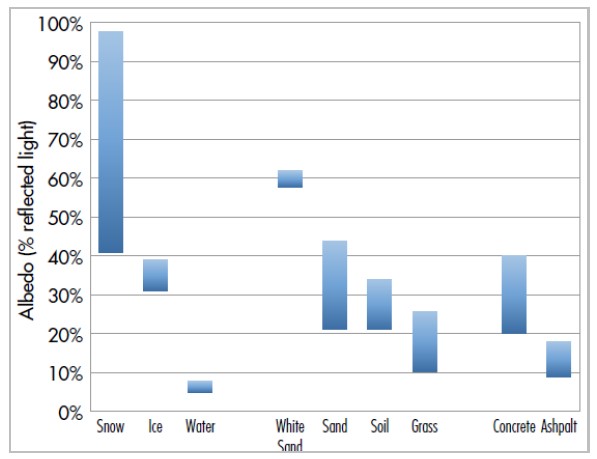

Typically, albedo is site-specific, with the type of surface beneath the model

determining the albedo of the area. Observations show that these values are often not

constant, with changes occurring daily and at seasonal intervals. Figure 6 illustrates

the range of albedo values corresponding to different surfaces.

Albedo ranges for different surfaces

Naturally occurring lighter surfaces such as snow and ice return the highest albedo

values (up to about 90% in some cases) while soil and grass delivers a peak albedo of

about 35%. It is clear that by incorporating certain design changes to utilize albedo, a

considerable bifacial gain from the system is possible.

A good starting point is to ascertain the composition on solar radiation, i.e. the ratio

of direct to diffused radiation. Locations where conditions of high-diffused radiation

prevail are prime candidates for deployment of bifacial systems as the bifacial ratio of

the selected module ties in to the site conditions. Site latitude, proximity to

geographic features such as coastal regions etc. determine the diffused component of

radiation and ultimately the bifacial gain from the system.

While albedo for a location is predetermined by its location and site conditions, it is

possible to engineer conditions to enhance albedo and boost generation. One such

technique is selective coating the ground surface with white paint or a reflective

surface as shown in Figure 7.

Figure 7: Selective coating of ground surface6

Selective coating is economically viable for rooftop or small plants without affecting

the CAPEX significantly. This is not practical for utility scale projects and hence

techniques that are more practical are employed, some of these are;

- MMS height

- MMS design

- Greater tilt

- Larger pitch

The purpose of raising the MMS height is to facilitate capture of additional diffused

albedo light at the rear surface. Increasing the height also results in less intense

shadows on the rear side of the module, thereby decreasing the impact of shading.

Electrical mismatch is maintained at a minimum as rear modules in a string are exposed

to more homogenous reflected radiation. Where MMS height for monofacial modules is

typically 1m, in bifacial systems a height between 1m of 2m is common. Increasing the

MMS height further results in diminishing returns. On the downside, increased MMS height

presents challenges during installation and O&M activity.

The same holds for trackers, where the use of bifacial modules has been shown to produce

significantly higher gains than bifacial modules installed on fixed tilt MMS. Evidence

of this is the high proportion of projects with bifacial modules currently in

development use trackers. Results presented by tracker manufacturer Soltech show the

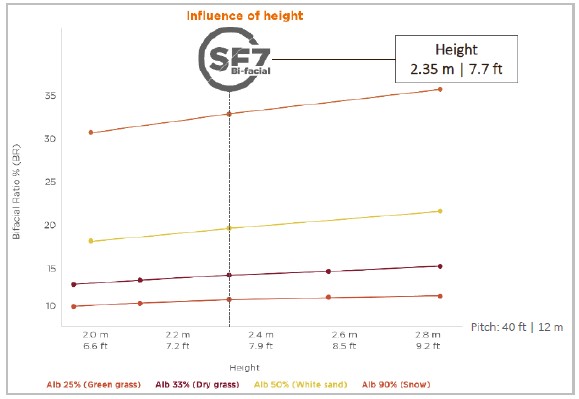

influence of MMS height in Figure 8.

Figure 8: Influence of height on bifacial ratio7

It can be seen that influence of height beyond a certain limit results in diminishing

returns8. The data is presented for different surfaces (albedo).

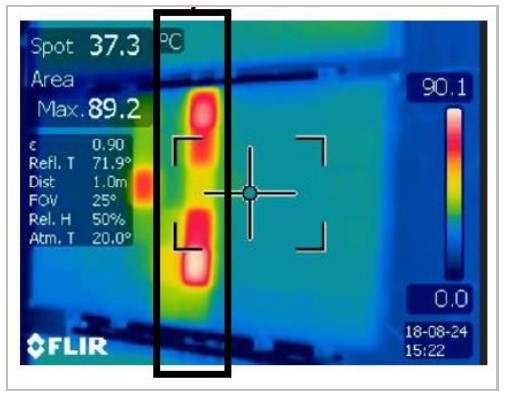

MMS designs for bifacial application have changed on the rear side to reduce shading from

reflected light. As current in bifacial modules is higher, shading can result in

formation of hotspots (Figure 9), posing a fire hazard.

Figure 9: Shading from the torque tube resulting in hotspot9

For bifacial modules on fixed tilt MMS, higher tilt angles are implemented to increase

exposure of the rear side to diffused and reflected light. A caveat however is the

increased load and a structure susceptible to higher wind loading. Compensating for

these may affect project IRR. For systems at particularly high latitudes, inter row

shading concerns may arise if a sufficient pitch is not maintained. In tracking plants,

the gain can be expected to vary more significantly than a fixed tilt system.

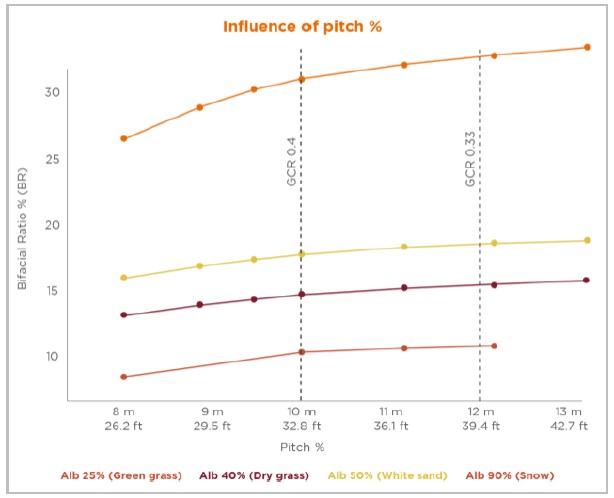

Another effective mechanism to increase the reflective area and diffused light is by

increasing the pitch as shown in Figure 10. Ground Coverage Ratio (GCR) is defined as

the ratio of collector width to pitch. GCR and tilt are connected as an increase in tilt

will require an increase in pitch to avoid inter row shading and in the case of bifacial

systems, higher albedo for the system. Increase in pitch also proves accessibility for

O&M activity.

Figure 10: Effect of pitch on bifacial ratio10

Increasing the inter row spacing has a positive effect on the bifacial ratio which

delivers a higher energy output. Although the linear trend is proportion, beyond a

certain value, the graph tends to flatten out and the returns diminish. Beyond this

critical value, cabling, infrastructure and cost of additional land will add to CAPEX

thereby making the project less lucrative. The appropriate pitch for a site depends on

project location, MMS design and tilt in the case of fixed tilt system.

When bifacial modules are paired with trackers, the energy gains have been shown to be

significantly higher than a bifacial on fixed tilt installation. This is because

trackers have a greater impact on the albedo and GCR, two key parameters that impact

rear side generation as shown in simulated results presented in Figure 11.

Figure 11: Influence of albedo (left) and GCR (right) on the two sides of

bifacial modules11

From the discussion, to configuring an optimal bifacial PV plant, site conditions are

considered in conjunction with the methods listed above to arrive at an optimal solution

that fulfills commercial and technical benchmarks of the project.

CURRENT SHORTCOMINGS

At present, modules are being tested and certified to IEC - 61215 which is inadequate for

measuring rear side generation of bifacial modules. A new standard is being developed by

the International Electrotechnial Commission (IEC) which shall include procedures to

measure IV characteristics of bifacial devices in natural or simulated environments. The

hurdle lies in the measurement method and determining the nameplate rating.

Presently, the available simulation software’s possess limitations in simulation energy

yields of bifacial systems which is down to the infancy of the technology. The absence

of reliable fields data to validate models can result in high uncertainty in predicted

yields which makes for non-bankable results.

APPLICATION OF BIFACIAL SYSTEMS

Their unique design makes bifacial modules useful where the use of monofacial modules

would not justifiable. Some areas of the application for bifacial modules are;

- Primarily in large PV fields utilizing trackers for further enhancement in energy

yields.

- As railings - where they are installed vertically.

- For soundproofing in building integrated PV systems.

- In snow heavy locations – due to high albedo, bifacial gain would be significant.

Such systems can produce energy all year.

- On Carports – With the emergence of EV’s these can serve to power charging points

Download as PDF